Although there are a wide variety of steel grades, they may be simplified down to a select few primary categories of steel. One of these is mild steel, which has recently emerged as a material seeing increased demand. This is mostly because of the material’s outstanding weldability and machinability, amongst other properties. Let’s discuss the fundamental aspects of the material, such as its manufacturing process and various applications.

What is Mild Steel?

Mild steel is a subcategory of carbon steel with a relatively small quantity of carbon; in fact, it is sometimes referred to as “low carbon steel.” Although the specific ranges can change depending on the source, the amount of carbon commonly present in mild steel is between 0.05% and 0.25% by weight. On the other hand, heavier carbon steels are typically defined as having a carbon content between 0.30% and 2.0%. If more carbon were added to the steel, it would be considered cast iron rather than steel.

Because it is not alloy steel, mild steel does not include significant quantities of other elements except iron. For example, you will not discover significant quantities of chromium, molybdenum, or any other alloying components in mild steel. As a result of the comparatively low amounts of carbon and alloying elements, it possesses several characteristics that set it apart from steels with larger carbon and alloy contents.

How is Mild Steel Made?

The production process for mild steel is comparable to that of other types of carbon steel. Using coal and iron ore together is a standard technique for accomplishing this goal. After the coal and iron ore have been mined from the soil, they are combined in a blast furnace to undergo the melting process.

After it has been melted, the combination is transferred to a different furnace, where it remains until any impurities it may contain are burned out, along with any other changes that need to be made to the chemical makeup of the mild steel. After that, the steel is allowed to harden into a rectangular form while it is allowed to cool. The size of the slab of mild steel is then reduced, often accomplished by using techniques known as hot rolling or cold drawing.

Why Are Mild Steel Plates Commonly Used?

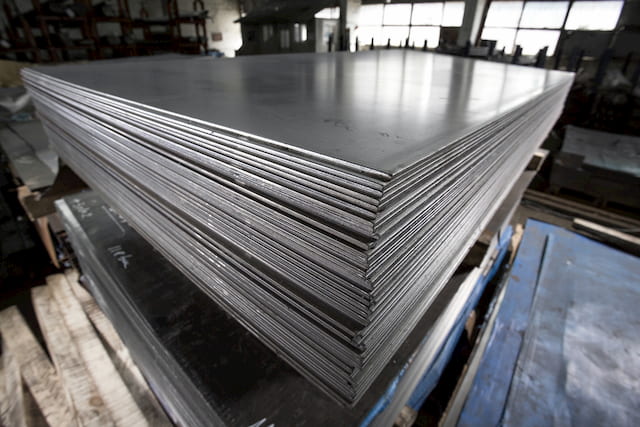

Plates of mild steel can be produced by enormous steel manufacturing facilities or smaller, more specialized companies. One of the many forms of steel that may be supplied to customers is steel plates. Other forms of steel that can be supplied include steel bars, sheets, chunks, and rolls, and that’s just the beginning. Steel plates are commonly used in construction. MS plates are extensively employed in various construction and military industries.

The applications for a steel plate add another layer of significance to the mild steel plate grades, constituents, and specifications that make up the plate. The shape of the plate in its condition of mild steel is rectangular, and it is employed in various mechanical and industrial sectors for use in construction projects such as roof construction, building structures, and a great deal more.

These are used in shipbuilding, barges, and other offshore machinery. They may be produced as structural parts, or they may be implemented as fixed pieces. Either way, they are structural components.

Take Away

Mild steel is one of the steel varieties used most frequently because it is suitable for producing goods in various business sectors. There are various applications for mild steel, including structural steel, autos, furniture, fences, and lots more.