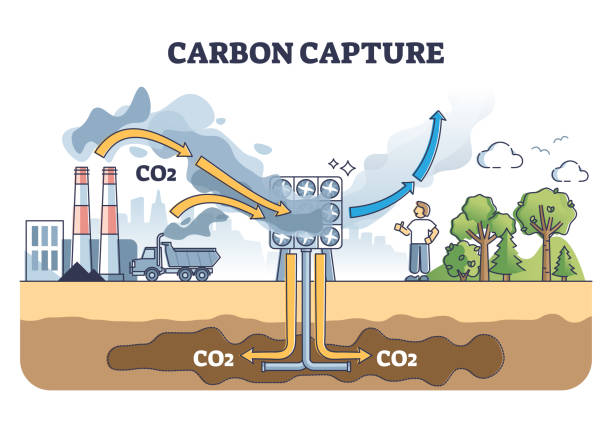

Carbon capture is an essential technology aimed at reducing greenhouse gas emissions from industrial sources. It is pivotal in mitigating climate change by capturing carbon dioxide (CO2) emissions before they enter the atmosphere. This article explores how carbon capture works in industrial settings, its various methods, and its significance.

The Basics of Carbon Capture

Carbon capture involves three primary stages: capturing the CO2, transporting it, and storing it securely. The process typically targets large point sources of CO2 emissions, such as power plants, cement factories, and steel mills. By intercepting emissions at their source, carbon capture is one of the best industrial solutions to reduce the carbon footprint of these industries.

Methods of Carbon Capture

- Pre-Combustion Capture: In pre-combustion capture, CO2 is removed before the fuel is burned. This method involves gasifying fossil fuels to produce a mixture of hydrogen and carbon monoxide. The carbon monoxide then reacts with water to form CO2 and hydrogen. The CO2 is separated, leaving hydrogen, which can be used as a clean fuel. Pre-combustion capture is commonly used in integrated gasification combined cycle (IGCC) plants.

- Post-Combustion Capture: Post-combustion capture involves extracting CO2 from the flue gases produced after the combustion of fossil fuels. This method is particularly relevant for existing power plants and industrial facilities because it can be retrofitted to current infrastructure. Chemical solvents, such as amines, absorb CO2 from the flue gases. The CO2-rich solvent is then heated to release pure CO2, which can be collected and transported for storage.

- Oxy-Fuel Combustion: Oxy-fuel combustion burns fuel in pure oxygen instead of air, which results in a flue gas that is primarily water vapor and CO2. This simplifies the separation process because the flue gas has a higher concentration of CO2. The water vapor is condensed, leaving behind a stream of CO2 ready for capture. Oxy-fuel combustion is still in the experimental stage but shows promise for future applications.

Transport and Storage of Captured CO2

Once captured, CO2 must be transported to a storage site. Transportation typically occurs through pipelines, although ships and trucks can also be used. Pipelines are the most efficient and cost-effective method for large volumes of CO2 over long distances.

The final stage is the storage of CO2, known as sequestration. This involves injecting CO2 into deep geological formations, like depleted oil and gas fields, saline aquifers, or unmineable coal seams. These formations are carefully selected to ensure they can securely contain CO2 for thousands of years. Enhanced oil recovery (EOR) is a method that utilizes captured CO2 to extract additional oil from reservoirs, providing both storage and economic benefits.

Significance and Challenges

Carbon capture and storage (CCS) is an important technology for achieving global climate targets. It enables industries that are difficult to decarbonize, such as cement and steel production, to reduce their emissions significantly. Additionally, CCS can complement renewable energy sources by dealing with the intermittency of wind and solar power.

However, CCS faces several challenges. The high cost of capture technology, energy requirements for the capture process, and the need for extensive infrastructure are significant hurdles. Public acceptance and regulatory frameworks also play crucial roles in the widespread adoption of CCS.