Epoxy adhesives are a popular choice for many industries, ranging from aerospace to automotive. Although there are many types of adhesive products available, Two Component Epoxy Adhesives (2K EP) offer superior strength and flexibility that make them ideal for a variety of applications. In this blog post, we will discuss the benefits of using 2K EP adhesives and why they are an excellent choice for many industrial projects. We will also explore how to choose the right epoxy adhesive for your application and how to properly use it for optimal results. Let’s get started!

Explanation

Two component epoxy adhesives have been around since the 1940s and have become increasingly popular in recent years due to their strong bonding properties. Whether you’re looking for an adhesive to bond metal, plastics, rubber, wood, or glass, two component epoxies are up for the challenge—and more. In this blog post, we’ll discuss what two component epoxy adhesives are, how they work and why they’re so effective. We’ll also talk about some of the different types of two component epoxies available on the market today and when it makes sense to use them. So if you need a reliable adhesive that can handle even the toughest jobs, read on!

Uses Of Two Component Epoxy Adhesives

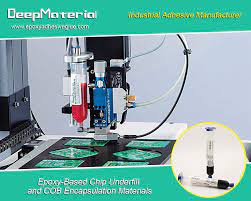

Epoxy adhesives have become an indispensable tool in modern industry. They’re often used in aerospace, automotive, and medical applications, as well as countless other industries. But what makes them so useful? The answer lies in their two-component nature: Epoxy adhesives consist of a resin and a hardener that work together to form an incredibly strong bond once they are cured. In this article, we will discuss the advantages of two-component epoxy adhesives and how they can be put to use in different industrial settings.

Advanced Option

When you think about adhesives, you likely think of glue or tape. But what if there was a more advanced option for connecting two materials together? Two component epoxy adhesives offer the perfect solution! These solutions are used in a variety of industries, from automotive to aerospace and many more. Not only are they incredibly strong and durable, but they also boast chemical and temperature resistance. So if you’re looking for an adhesive that will last through extreme conditions, this is it. In this blog post, we’ll explore the ins and outs of two component epoxy adhesives and how they can help with your next project. Read on to learn more!

Different From Other Adhesives

Two component epoxy adhesives have become popular in recent years. They are used in a wide variety of industries, ranging from automotive to medical. But what makes them so appealing? In this blog post, we will explore the advantages of using two part epoxy adhesives. We will look at their properties and how they differ from other types of adhesives. We’ll also discuss the application process and guidelines to ensure a successful bond. So if you’re considering using two part epoxy adhesives for your next project, read on to learn more!

you can pay a visit to https://www.epoxyadhesiveglue.com/

Conclusion

The increasing demand for high performance adhesives has led to the development of two component epoxy adhesives. These adhesives are widely used in a variety of applications, from automotive and aerospace to medical device and electronics assembly. Two component epoxy adhesives are made up of two parts – a resin and a hardener – which when mixed together form a strong bond that is resistant to temperature, vibration, and moisture. In this article, we will go over the basics of two component epoxy adhesives, their benefits and applications, as well as tips for selecting the right adhesive for your project.