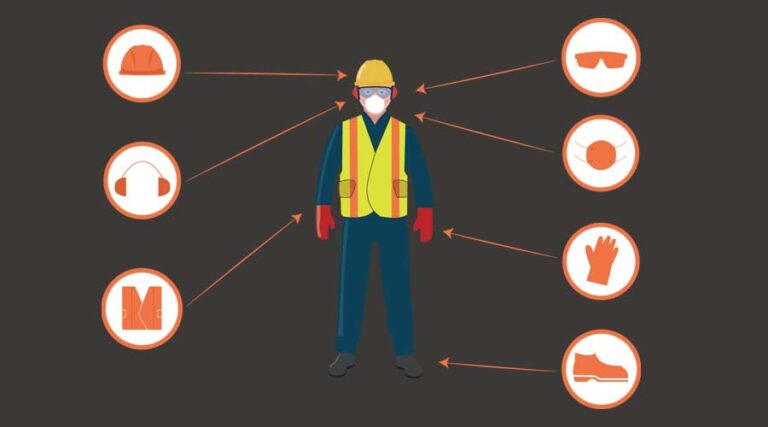

On most construction sites, hard hats, safety vests, and steel-toed boots abound. The basics are taken care of. Yet what’s rarely talked about are the PPE requirements that are overlooked. These are the ones that matter most when something goes wrong. And they’re not niche regulations or uncommon cases. They’re basic safety requirements that are passed over, downgraded or applied incorrectly every day on job sites across America.

It’s not that safety managers don’t care; it’s that specific PPE requirements don’t feel urgent until someone is injured. By then, it’s too late to fill the gaps.

Protection For the Head That Gets Downgraded

Hard hats are required on essentially every construction site. Yet the level of protection for what’s currently on workers’ heads varies greatly. Most sites use Type 1 helmets because it meets general expectations and that’s what people are used to seeing. But Type 1 only protects from vertical impacts – something falling from above.

This is problematic in demolition jobs, bridge constructs and any other space where a worksite might get struck laterally. A piece of equipment swings in a lateral direction; a worker turns into a beam; debris comes flying in from an angle. None of these conditions are protected under standard Type 1 protection. Instead, workers need a proper Type 2 hard hat rated for lateral impact, but this increase seldom happens until after an incident report generates discussion.

The difference isn’t even that great. But instead of recognizing that a hard hat is a hard hat, workers stay with inadequate protection for the hazards present.

Respiratory Protection That Actually Fits

Dust masks are provided on construction sites across the board. What isn’t done nearly enough? Fit testing for respirators.

When cutting concrete, sandblasting or working with certain chemicals, a dust mask isn’t good enough. Workers require respirators, and those respirators need to adequately seal against their face. Beards, improper sizes or model all create gaps that allow contaminants in. Fit testing catches these red flags before exposure occurs.

Here’s the best part: OSHA requires fit testing for tight-fitting respirators when respirators are required in the first place. Yet this requirement is overlooked and misunderstood far too often. Sites will provide N95s or half-faces without ever checking if they actually work for each individual worker. The respirator is there, so the box is checked – even though the person may receive no benefit from it.

It takes about 15 minutes per worker per year to fit test. Or it takes one occurrence of someone developing a respiratory condition that never should have come to be.

Eye Protection Beyond Safety Glasses

Safety glasses are a dime a dozen on construction sites; what’s less common, however, is proper eye protection for certain tasks. Safety glasses protect from flying debris and basic hazards; they don’t protect from chemical splash, welding operations or anything with enough fine dust to go around frames.

Chemicals need goggles with proper seals. Welding requires specific shades dependent on the operation being done at that moment. Grinding creates particles coming from every direction, not just in front of where someone is working. Each situation requires specific PPE protection that safety glasses cannot afford.

The theme continues: sites will supply one type of eye protection and figure it covers everything. Workers get stuck with something inadequate simply because it’s what was available. The hazards of individual tasks go overlooked because they’re not comprehensive.

Fall Protection Beyond Harnesses

Everyone knows that workers need harnesses at height, for plenty of good reasons. What’s overlooked, however, is full fall protection systems. A harness won’t protect a worker from injuries; it’s one small component.

The anchor point must support loads involved to catch someone mid-fall. The lanyard/self-retracting lifeline must measure correctly for the work environment. Below the worker must be cleared so they don’t plummet to the ground (or another level) during descent. And someone must have a rescue plan to bring a suspended worker down after their fall gets caught.

These aren’t nit-picky details; they’re the difference between functioning fall protection systems and failed ones when the time comes. But sites regularly overlook these aspects while checking the box for harnesses being worn.

Hearing Protection Intermittently

Continuous noise gets attention; jackhammers, heavy machinery and constant operation typically calls for actual hearing protection requirements that are upheld. Intermittent noise exposure goes unnoticed, and yet just as easily destroys hearing over time.

Nail guns, impact wrenches, concrete saws used sporadically throughout the day generate noise spikes that add up to considerable noise exposure. Thus, workers often forego hearing protection for “quick jobs” that may happen seven times a shift. Unfortunately, this cumulative effect harms hearing just as badly as sustained exposure, but because one loud exposure in passing doesn’t seem that bad, there’s no protection provided.

It’s simple to fix: supply hearing protection that’s comfortable enough to wear all day long and stress a culture where it’s kept on even during brief high-decibel tasks. But this requires understanding intermittent noise as noise instead of something that only counts if constant.

The Inspection Gap and Replacement

Even when sites have proper PPE, there’s seldom a system set up for regular inspection and timely replacement. Hard hats come down from use well beyond expiration dates. Safety harnesses earn frayed webbing that goes unnoticed until falls happen. Respirator cartridges remain in circulation beyond usefulness. Gloves earn small tears that negate their protective purposes.

PPE isn’t lifelong; it deteriorates through exposure, time and use. Every piece has inspection requirements and replacement timelines, but this is seen as optional instead of mandatory. The equipment is there so that’s good enough, even when it’s effectively useless at this point in time.

Systems That Actually Work

The general trend among all these missing requirements is that systems, not just equipment purchased, need to be in place.

Type 2 helmets do nothing if no one assesses which work areas require them in the first place. Respirators make no difference without fitting them properly. Fall protection equipment does nothing without adequate training/recovery plans.

There’s no added complication to regulations required; it’s simply a matter of acknowledging that PPE requirements go beyond having PPE accessible on site, they involve assessment, training, ongoing interaction and replacement just as much as initial procurement levels do through proper channels.

When sites approach PPE as checkbox activities, the failures occur in the spaces where protection is needed most – and those failures tend to emerge at the most inopportune times – and they’re even worse than anticipated gaps previously observed.